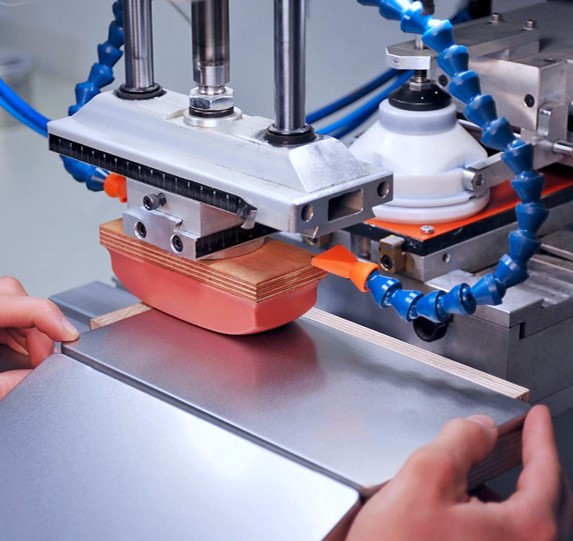

Excellent printing quality with optimal cost

SILASTOSIL® PP line liquid silicone rubbers are two-component, room-temperature-vulcanizing silicone rubbers (RTV-2) developed for producing silicone printing pads. They are well suited for any type of inks, provide high elongation rates and outstanding mechanical strengths. Their ink compatibilities are excellent, can be used on different surfaces including plastics and rubbers, composites, metal, aluminum, glass, plexiglass, wood, fabric, leather, clay, ceramic and porcelain.

Silicone printing pads produced with SILASTOSIL® PP provide excellent print qualities with long service life.

For further information about our solutions for Pad Printing, please contact us. Our experts will assist you in making the right choices to secure the product properties you seek.

PRODUCT RECOMMENDATIONS

> SILASTOSIL® PP 1114 A/B

Room Temperature Curing Silicone Rubber (RTV-2)

Pourable, condensation-curing (100:3 mixing ratio), two-component silicone rubber that vulcanizes at room temperature. Ideal for producing longlife silicone printing pads. Very good flowability, excellent self-deaeration ability, fast and non-shrink cure, enables rapid demolding time, long-term consistency, high tear resistance. In white colour.

Hardness 14 Shore A.

> SILASTOSIL® PP 1114 A/B PINK

Room Temperature Curing Silicone Rubber (RTV-2)

Pourable, condensation-curing (100:3 mixing ratio), two-component silicone rubber that vulcanizes at room temperature. Ideal for producing longlife silicone printing pads. Very good flowability, excellent self-deaeration ability, fast and non-shrink cure, enables rapid demolding time, long-term consistency, high tear resistance. In pink colour.

Hardness 14 Shore A.

> SILASTOSIL® PP 1130 A/B

Room Temperature Curing Silicone Rubber (RTV-2)

Pourable, condensation-curing (100:3 mixing ratio), two-component silicone rubber that vulcanizes at room temperature. Ideal for producing longlife silicone printing pads. Very good flowability, excellent self-deaeration ability, fast and non-shrink cure, enables rapid demolding time, long-term consistency, high tear resistance, in white colour.

Hardness 30 Shore A.

> TERRAFLUID® DM 20

INCI Name : Dimethicone

CAS No. 63148-62-9

Linear, non-reactive polydimethylsiloxane with a viscosity of approx. 20 mm²/s.

It is used as additive for RTV-2 silicone rubbers to adjust the elasticity and hardness of the silicone printing pad without affecting the mechanical strenghts and service life.

> TERRAFLUID® DM 35

INCI Name : Dimethicone

CAS No. 63148-62-9

Linear, non-reactive polydimethylsiloxane with a viscosity of approx. 35 mm²/s.

It is used as additive for RTV-2 silicone rubbers to adjust the elasticity and hardness of the silicone printing pad without affecting the mechanical strenghts and service life.

> TERRAFLUID® DM 50

INCI Name : Dimethicone

CAS No. 63148-62-9

Linear, non-reactive polydimethylsiloxane with a viscosity of approx. 50 mm²/s.

It is used as additive for RTV-2 silicone rubbers to adjust the elasticity and hardness of the silicone printing pad without affecting the mechanical strenghts and service life.

> SILASTOSIL® CATALYST T20

Tin Catalyst

Curing agent for condensation-cure RTV-2 silicone rubbers.

> SILASTOSIL® CATALYST T30

Tin Catalyst

Curing agent for condensation-cure RTV-2 silicone rubbers.

> SILASTOSIL® CATALYST T40

Tin Catalyst

Curing agent for condensation-cure RTV-2 silicone rubbers.

> SILASTOSIL® CATALYST T50

Tin Catalyst

Curing agent for condensation-cure RTV-2 silicone rubbers.

> SILASTOSIL® CATALYST T100

Tin Catalyst

Curing agent for condensation-cure RTV-2 silicone rubbers

APPLICATIONS

> Elastomers for Pad Printing

> Silicone Printing Pads

> Keyboards

> Automotive industry

> Toys

> Sports equipment