To make impressive productions

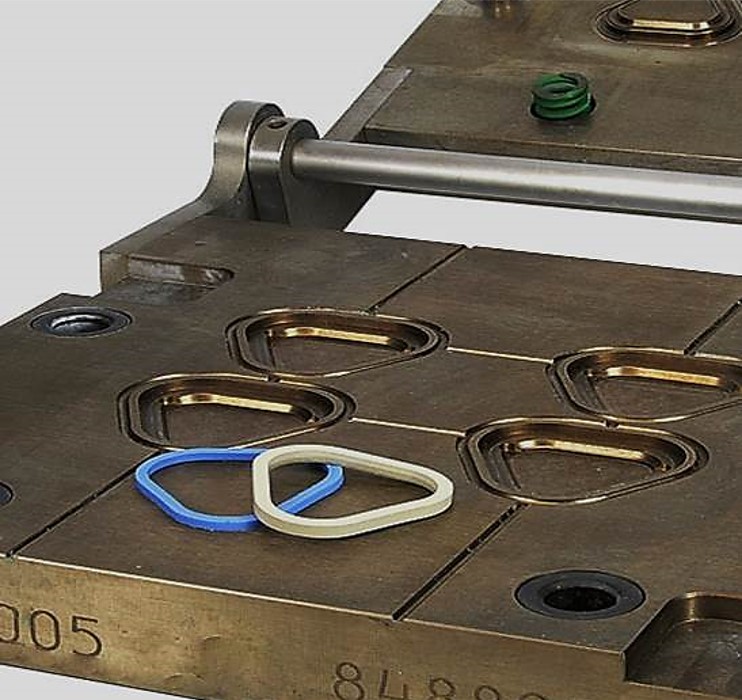

For the industries which make productions by using plastics, rubbers and elastomers, and non-ferrous metals by injection molding, compression molding or extrusion, TERRA offers a specific range of process aids.

Liquid and solid silicone rubbers, silicone fluids and silicone emulsions for release and mold release, and other complementary process aids help to make top quality productions in large amounts at competitive costs.

Innovative solutions with proven performances

Having years of experience in silicone based process aids, TERRA offers innovative solutions with proven performances. The selective product range are used in various industries, including automotive parts, hose, gasket, seal, O-ring, conveyor belt, EPDM rubber profile for door and window, insulation panel, baby care, foot care and medical care articles, kitchenware, sport equipments, electrics, electronics and lighting, wire and cable, insulators, arresters and cable accessories, building and construction elements, furniture, home decoration articles, thermal molding shoe sole, and so on:

> Silicone Rubbers & Additives

> RTV-2 Silicone Rubber for Molding & Mold Making

> Silica

> Silicone Emulsion for Release & Lubrication

> Primers & Bonding Agents for Silicone Rubbers

For further information about our solutions used in Industrial Molding & Foundry applications, please contact us. Our experts will assist you in making the right choices to secure the product properties you seek.

PRODUCT RECOMMENDATIONS

> TERRASIL® RA 1020

Silicone Fluid Emulsion

Modified oil-in-water emulsion of a high-viscosity polydimethylsiloxane with excellent wetting, penetrating and release properties. It is used as a universal lubricant and release agent in rubber processing. Furthermore, the emulsion improves the brigthness, provides resistance to acids, weathering, UV and radiation, and supports an easy installation of the products by imparting elasticity.

> TERRASIL® RA 1025

Silicone Fluid Emulsion

Modified oil-in-water emulsion of a high-viscosity polydimethylsiloxane with excellent wetting, penetrating and release properties. It is used as a universal lubricant and release agent in rubber processing. Furthermore, the emulsion improves the brigthness, provides resistance to acids, weathering, UV and radiation, and supports an easy installation of the products by imparting elasticity.

> TERRASIL® RA 1025-T

Silicone Fluid Emulsion

Modified oil-in-water emulsion of a high-viscosity polydimethylsiloxane with excellent wetting, penetrating and release properties. It is used as a universal lubricant and release agent in rubber processing. Furthermore, the emulsion improves the brigthness, provides resistance to acids, weathering, UV and radiation, and supports an easy installation of the products by imparting elasticity.

> TERRASIL® RA 1030

Silicone Fluid Emulsion

Modified oil-in-water emulsion of a high-viscosity polydimethylsiloxane with excellent wetting, penetrating and release properties. It is used as a universal lubricant and release agent in rubber processing. Furthermore, the emulsion improves the brigthness, provides resistance to acids, weathering, UV and radiation, and supports an easy installation of the products by imparting elasticity.

> TERRASIL® RA 1035

Silicone Fluid Emulsion

Modified oil-in-water emulsion of a high-viscosity polydimethylsiloxane with excellent wetting, penetrating and release properties. It is used as a universal lubricant and release agent in rubber processing. Furthermore, the emulsion improves the brigthness, provides resistance to acids, weathering, UV and radiation, and supports an easy installation of the products by imparting elasticity.

> TERRASIL® RA 1035-T

Silicone Fluid Emulsion

Modified oil-in-water emulsion of a high-viscosity polydimethylsiloxane with excellent wetting, penetrating and release properties. It is used as a universal lubricant and release agent in rubber processing. Furthermore, the emulsion improves the brigthness, provides resistance to acids, weathering, UV and radiation, and supports an easy installation of the products by imparting elasticity.

> TERRASIL® RA 1040

Silicone Fluid Emulsion

Modified oil-in-water emulsion of a high-viscosity polydimethylsiloxane with excellent wetting, penetrating and release properties. It is used as a universal lubricant and release agent in rubber processing. Furthermore, the emulsion improves the brigthness, provides resistance to acids, weathering, UV and radiation, and supports an easy installation of the products by imparting elasticity.

> TERRASIL® RA 2040

Silicone Fluid Emulsion

Modified oil-in-water emulsion of a high-viscosity polydimethylsiloxane with excellent wetting, penetrating and release properties. It is used as a universal lubricant and release agent in rubber processing. Furthermore, the emulsion improves the brigthness, provides resistance to acids, weathering, UV and radiation, and supports an easy installation of the products by imparting elasticity.

> TERRASIL® RA 1054

Silicone Wax Emulsion

High viscosity silicone wax emulsion with high alkali resistance. It is mainly used as lubricant and release agent in heat set web offset printing.

> TERRASIL® RA 5050

Silicone Fluid Emulsion

Nonionic oil-in-water emulsion of a polysiloxane containing alkyl and aralkyl organic groups. It is used for the formulation of release agents for the thermal moulding of rubber, plastics, and low-melting non-ferrous metals. It is mainly recommended for release problems where the demoulded parts are subsequently painted, printed, coated or bonded.

> TERRASIL® RA 5055

Silicone Fluid Emulsion

Nonionic oil-in-water emulsion of a polysiloxane containing alkyl and aralkyl organic groups. It is used for the formulation of release agents for the thermal moulding of rubber, plastics, and low-melting non-ferrous metals. It is mainly recommended for release problems where the demoulded parts are subsequently painted, printed, coated or bonded.

> TERRASIL® PRA 3000

Silicone Resin Emulsion

Solvent-based, ready-to-use silicone emulsion for mold removal in polyurethane resin casting, ideal for rigid and semi-rigid polyurethane resin molding.

> TERRASIL® PRA 3150

Silicone Resin Emulsion

Solvent-based, ready-to-use silicone emulsion for mold removal in polyurethane resin casting, ideal for rigid and semi-rigid polyurethane resin molding.

> TERRASIL® PRA 3147

Silicone Resin Emulsion

Solvent-based, ready-to-use silicone emulsion for mold removal in polyurethane resin casting, ideal for rigid and semi-rigid polyurethane resin molding.

> TERRASIL® PRA 5007

Silicone Resin Emulsion

Solvent-based lubricant and release agent to facilitate mold removal in polyurethane and polyester casting applications. It is specificly well suited for producing polyester cast furniture parts, decorative wall panels, ornaments, and home accessories. It provides easy demolding without casualty, and prolongue the mold life.

> TERRASIL® PRA 8300

Silicone Resin Emulsion

Solvent-based, high-concentrate silicone emulsion for mold removal in polyurethane resin casting. It is mainly recommended for release problems where the demoulded parts are subsequently painted, printed, coated or bonded.

> TERRASIL® PRA 8315

Silicone Resin Emulsion

Solvent-based, ready-to-use silicone emulsion for mold removal in polyurethane resin casting, ideal for shoe insole molding. It is mainly recommended for release problems where the demoulded parts are subsequently painted, printed, coated or bonded.

> TERRASIL® PRA 8317

Silicone Resin Emulsion

Solvent-based, ready-to-use silicone emulsion for mold removal in polyurethane resin casting, ideal for shoe insole molding. It is mainly recommended for release problems where the demoulded parts are subsequently painted, printed, coated or bonded.

> WACKER® TN

Functional Silicone Fluid

Modified silicone fluid of medium viscosity whose special chemical structure imbues it with the benefits of silicone fluids and mineral oils. is used for the formulation of release agents for thermal molding of rubber, plastics and low-melting nonferrous metals. It is superior to conventional silicone fluids when the finished parts are subsequently to be painted, printed, coated or bonded.

> WACKER® TNE 50

Silicone Fluid Emulsion

Nonionic oil-in-water emulsion of a polysiloxane containing alkyl and aralkyl organic groups. It is used for the formulation of release agents for the thermal moulding of rubber, plastics, and low-melting non-ferrous metals. It is mainly recommended for release problems where the demoulded parts are subsequently painted, printed, coated or bonded.

> SILASTOSIL® M 3005

Room Temperature Curing Silicone Rubber (RTV-2)

Pourable, condensation-curing (100:3 mixing ratio), two-component silicone rubber that vulcanizes at room temperature. Ideal viscosity and optimal curing time for shoe sole molding and mold making. In white color.

Hardness 5-7 Shore A.

> SILASTOSIL® M 4010

Room Temperature Curing Silicone Rubber (RTV-2)

Pourable, condensation-curing (100:3 mixing ratio), two-component silicone rubber that vulcanizes at room temperature. Ideal viscosity and optimal curing time for shoe sole molding and mold making. In white color.

Hardness 8-10 Shore A.

> SILASTOSIL® M 2915

Room Temperature Curing Silicone Rubber (RTV-2)

Pourable, condensation-curing (100:3 mixing ratio), two-component silicone rubber that vulcanizes at room temperature. Ideal viscosity and optimal curing time for shoe sole molding and mold making. In white color.

Hardness 13-15 Shore A.

> SILASTOSIL® M 3020

Room Temperature Curing Silicone Rubber (RTV-2)

Pourable, condensation-curing (100:3 mixing ratio), two-component silicone rubber that vulcanizes at room temperature. Ideal viscosity and optimal curing time for shoe sole molding and mold making. In white color.

Hardness 17-22 Shore A.

> SILASTOSIL® LR 3030 A/B

Liquid Silicone Rubber (LSR)

Paste-like, easily-pigmentable two-component silicone rubber compound with short curing times. Its vulcanizates are noted for their high transparency and excellent mechanical and electrical properties. Clear transparent, colorless and odorless, non-toxic, food contact (FDA confirmed), reduced volatile content.

Narrow Shore hardness range from 27 to 33 Shore A.

> SILASTOSIL® LR 3040 A/B

Liquid Silicone Rubber (LSR)

Paste-like, easily-pigmentable two-component silicone rubber compound with short curing times. Its vulcanizates are noted for their high transparency and excellent mechanical and electrical properties. Clear transparent, colorless and odorless, non-toxic, food contact (FDA confirmed), reduced volatile content.

Narrow shore hardness range from 37 to 43 Shore A.

> SILASTOSIL® LR 3045 A/B

Liquid Silicone Rubber (LSR)

Paste-like, easily-pigmentable two-component silicone rubber compound with short curing times. Its vulcanizates are noted for their high transparency and excellent mechanical and electrical properties. Clear transparent, colorless and odorless, non-toxic, food contact (FDA confirmed), reduced volatile content.

Narrow shore hardness range from 42 to 48 Shore A.

> SILASTOSIL® LR 3050 A/B

Liquid Silicone Rubber (LSR)

Paste-like, easily-pigmentable two-component silicone rubber compound with short curing times. Its vulcanizates are noted for their high transparency and excellent mechanical and electrical properties. Clear transparent, colorless and odorless, non-toxic, food contact (FDA confirmed), reduced volatile content.

Narrow Shore hardness range from 47 to 53 Shore A.

> SILASTOSIL® LR 3060 A/B

Liquid Silicone Rubber (LSR)

Paste-like, easily-pigmentable two-component silicone rubber compound with short curing times. Its vulcanizates are noted for their high transparency and excellent mechanical and electrical properties. Clear transparent, colorless and odorless, non-toxic, food contact (FDA confirmed), reduced volatile content.

Narrow Shore hardness range from 57 to 63 Shore A.

> SILASTOSIL® LR 3065 A/B

Liquid Silicone Rubber (LSR)

Paste-like, easily-pigmentable two-component silicone rubber compound with short curing times. Its vulcanizates are noted for their high transparency and excellent mechanical and electrical properties. Clear transparent, colorless and odorless, non-toxic, food contact (FDA confirmed), reduced volatile content.

Narrow Shore hardness range from 62 to 68 Shore A.

> SILASTOSIL® LR 3070 A/B

Liquid Silicone Rubber (LSR)

Paste-like, easily-pigmentable two-component silicone rubber compound with short curing times. Its vulcanizates are noted for their high transparency and excellent mechanical and electrical properties. Clear transparent, colorless and odorless, non-toxic, food contact (FDA confirmed), reduced volatile content.

Narrow Shore hardness range from 67 to 73 Shore A.

> SILASTOMER® LR 4040 A/B

Liquid Silicone Rubber (LSR)

Paste-like, easily-pigmentable two-component silicone rubber compound with short curing times. Its vulcanizates are noted for their high transparency and excellent mechanical and electrical properties. Clear transparent, colorless and odorless, non-toxic, food contact (FDA confirmed), medical grade (ISO 10993 confirmed), high purity, reduced volatile content.

Narrow shore hardness range from 37 to 43 Shore A.

> SILASTOMER® LR 4050 A/B

Liquid Silicone Rubber (LSR)

Paste-like, easily-pigmentable two-component silicone rubber compound with short curing times. Its vulcanizates are noted for their high transparency and excellent mechanical and electrical properties. Clear transparent, colorless and odorless, non-toxic, food contact (FDA confirmed), medical grade (ISO 10993 confirmed), high purity, reduced volatile content.

Narrow Shore hardness range from 47 to 53 Shore A.

> SILASTOMER® LR 4060 A/B

Liquid Silicone Rubber (LSR)

Paste-like, easily-pigmentable two-component silicone rubber compound with short curing times. Its vulcanizates are noted for their high transparency and excellent mechanical and electrical properties. Clear transparent, colorless and odorless, non-toxic, food contact (FDA confirmed), medical grade (ISO 10993 confirmed), high purity, reduced volatile content.

Narrow Shore hardness range from 57 to 63 Shore A.

> SILASTOSIL® LR 6430 A/B

Liquid Silicone Rubber (LSR)

Low-viscous, two-component silicone compound for injection molding with excellent processing properties. The vulcanized silicone rubber is noted for the good mechanical properties as well as for the excellent dielectrical behaviour. In gray colour. Ideal for high-voltage insulator and arrester.

Narrow Shore hardness range from 30 to 35 Shore A.

> SILASTOSIL® LR 6440 A/B

Liquid Silicone Rubber (LSR)

Low-viscous, two-component silicone compound for injection molding with excellent processing properties. The vulcanized silicone rubber is noted for the good mechanical properties as well as for the excellent dielectrical behaviour. In gray colour. Ideal for high-voltage insulator and arrester.

Narrow Shore hardness range from 38 to 40 Shore A.

> SILASTOSIL® LR 9640 A/B

Liquid Silicone Rubber (LSR)

Extreme low-viscous, two-component silicone compound for injection molding with excellent processing properties. The vulcanized silicone rubber is noted for the good mechanical properties as well as for the excellent dielectrical behaviour. In gray colour. Ideal for high-voltage insulator and arrester.

Narrow Shore hardness range from 40 to 42 Shore A.

> Holcosil® LR

Colorant

Liquid pigment paste for coloring RTV-2 and LSR liquid silicone rubbers, highly effective, easily dispersible. Food contact and skin contact, FDA confirmed.

> SILASTOSIL® HTV 9230

High Temperature Vulcanizing Silicone Rubber (HTV)

Peroxide cured vulcanizates made from this compound exhibit a unique combination of characteristics. They are noted for their good flexibility, high transparency, and mechanical properties. The compounds are easily pigmented with TERRACOLOR® Color Paste and have good processing characteristics.

Narrow shore hardness range from 27-32 Shore A.

> SILASTOSIL® HTV 9240

High Temperature Vulcanizing Silicone Rubber (HTV)

Peroxide cured vulcanizates made from this compound exhibit a unique combination of characteristics. They are noted for their good flexibility, high transparency, and mechanical properties. The compounds are easily pigmented with TERRACOLOR® Color Paste and have good processing characteristics.

Narrow shore hardness range from 37-42 Shore A.

> SILASTOSIL® HTV 9250

High Temperature Vulcanizing Silicone Rubber (HTV)

Peroxide cured vulcanizates made from this compound exhibit a unique combination of characteristics. They are noted for their good flexibility, high transparency, and mechanical properties. The compounds are easily pigmented with TERRACOLOR® Color Paste and have good processing characteristics.

Narrow shore hardness range from 48-52 Shore A.

> SILASTOSIL® HTV 9260

High Temperature Vulcanizing Silicone Rubber (HTV)

Peroxide cured vulcanizates made from this compound exhibit a unique combination of characteristics. They are noted for their good flexibility, high transparency, and mechanical properties. The compounds are easily pigmented with TERRACOLOR® Color Paste and have good processing characteristics.

Narrow shore hardness range from 60-65 Shore A.

> SILASTOSIL® HTV 9270

High Temperature Vulcanizing Silicone Rubber (HTV)

Peroxide cured vulcanizates made from this compound exhibit a unique combination of characteristics. They are noted for their good flexibility, high transparency, and mechanical properties. The compounds are easily pigmented with TERRACOLOR® Color Paste and have good processing characteristics.

Narrow shore hardness range from 68-73 Shore A.

> SILASTOSIL® HTV 9280

High Temperature Vulcanizing Silicone Rubber (HTV)

Peroxide cured vulcanizates made from this compound exhibit a unique combination of characteristics. They are noted for their good flexibility, high transparency, and mechanical properties. The compounds are easily pigmented with TERRACOLOR® Color Paste and have good processing characteristics.

Narrow shore hardness range from 78-82 Shore A.

> TERRAFLUID® DM 10

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 10 mm²/s.

> TERRAFLUID® DM 20

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 20 mm²/s.

> TERRAFLUID® DM 50

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 50 mm²/s.

> TERRAFLUID® DM 100

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 100 mm²/s.

> TERRAFLUID® DM 150

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 150 mm²/s.

> TERRAFLUID® DM 200

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 200 mm²/s.

> TERRAFLUID® DM 250

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 250 mm²/s.

> TERRAFLUID® DM 300

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 300 mm²/s.

> TERRAFLUID® DM 350

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 350 mm²/s.

> TERRAFLUID® DM 500

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 500 mm²/s.

> TERRAFLUID® DM 750

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 750 mm²/s.

> TERRAFLUID® DM 1000

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 1000 mm²/s.

> TERRAFLUID® DM 5000

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 5000 mm²/s.

> TERRAFLUID® DM 10000

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 10000 mm²/s.

> TERRAFLUID® DM 12500

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 12500 mm²/s.

> TERRAFLUID® DM 22500

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 22500 mm²/s.

> TERRAFLUID® DM 50000

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 50000 mm²/s.

> TERRAFLUID® DM 60000

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 60000 mm²/s.

> TERRAFLUID® DM 100000

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 100000 mm²/s.

> TERRAFLUID® DM 250000

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 250000 mm²/s.

> TERRAFLUID® DM 300000

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 300000 mm²/s.

> TERRAFLUID® DM 500000

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 500000 mm²/s.

> TERRAFLUID® DM 600000

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 600000 mm²/s.

> TERRAFLUID® DM 750000

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 750000 mm²/s.

> TERRAFLUID® DM 1000000

INCI Name : Dimethicone

CAS No. 63148-62-9

Dimethyl silicone fluid with a viscosity of approx. 1000000 mm²/s.

> TERRAFLUID® L 1053

Functional Silicone Fluid

A medium viscosity polyether functional polydimethylsiloxane which is completely water soluble. It can be used in a wide range of applications such as textile industry, polishes, cleaners, and plastics industry, and exhibits both special lubricant properties and antistatic action.

> TERRAFLUID® L 6560

Functional Silicone Fluid

A low viscosity aminoalkyl functional polydimethylsiloxane. It can be used as a component for rinse-off agents in automatic car washes. It improves the break-down and sheeting of the water film as well as conditioning effects and gloss level. It can be used in paint conditioners and paint polishes in order to provide superior gloss and detergent resistance. Gloss and depth of color are retained for a longer period of time.

> TERRASIL® PE 1040

Silicone Fluid Emulsion

Nonionic oil-in-water-emulsion of a medium viscosity polydimethylsiloxane dispersed in water. Even in diluted form, the emulsion is well stable with regard to shear stress. In addition, it exhibits excellent wetting and spreading properties. It can easily be incorporated into coldstirred formulations.

> TERRASIL® PE 2040

Silicone Fluid Emulsion

Nonionic oil-in-water-emulsion of a medium viscosity polydimethylsiloxane dispersed in water. Even in diluted form, the emulsion is well stable with regard to shear stress. In addition, it exhibits excellent wetting and spreading properties. It can easily be incorporated into coldstirred formulations.

> TERRASIL® PE 1060

Silicone Fluid Emulsion

Nonionic oil-in-water-emulsion of a medium viscosity polydimethylsiloxane dispersed in water. Even in diluted form, the emulsion is well stable with regard to shear stress. In addition, it exhibits excellent wetting and spreading properties. It can easily be incorporated into coldstirred formulations.

> TERRASIL® PE 2060

Silicone Fluid Emulsion

Nonionic oil-in-water-emulsion of a medium viscosity polydimethylsiloxane dispersed in water. Even in diluted form, the emulsion is well stable with regard to shear stress. In addition, it exhibits excellent wetting and spreading properties. It can easily be incorporated into coldstirred formulations.

> TERRASIL® RSN 1600 MQ

Alkylsilicone Resin (Silicone MQ Resin)

Pure white powder silicone resin. It can be compounded with polydimethylsiloxanes or dissolved in appropriate solvents like aromatic and non-aromatic hydrocarbons or lower alcohols. The solubility is excellent.

> WACKER HDK® H15

Pyrogenic Silica (Silicone Dioxide)

CAS No. 68611-44-9

Synthetic, hydrophobic, amorphous silica. High purity, in white color.

> WACKER HDK® N20

Pyrogenic Silica (Silicone Dioxide)

CAS No. 112945-52-5

Synthetic, hydrophilic, amorphous silica. High purity, in white color.

> HIFULL HB-151

Fumed Silica

Hydrophobic fumed silica modified with DDS (Dimethyldichlorosilane) with a specific surface area of 150m²/g. It is ideal for use in coatings, adhesives, sealants silicone sealants, silicone rubber, silicone elastomers, printing inks, cosmetics and unsaturated polyester.

> AEROSIL® R 972

Fumed Silica

Hydrophobic fumed silica modified with DDS (Dimethyldichlorosilane) with a specific surface area of 90-130m²/g. It is ideal for use in coatings, adhesives, sealants silicone sealants, silicone rubber, silicone elastomers, printing inks, cosmetics and unsaturated polyester.

> HJSIL R272

Fumed Silica

Hydrophobic fumed silica modified with DDS (Dimethyldichlorosilane) with a specific surface area of 90-130m²/g. It is ideal for use in coatings, adhesives, sealants silicone sealants, silicone rubber, silicone elastomers, printing inks, cosmetics and unsaturated polyester.

> HCSIL 151

Fumed Silica

Hydrophobic fumed silica which is produced after chemical post-treatment with DDS(Dimethyldichlorosilane). It is ideal for use in coatings, adhesives, sealants silicone sealants, silicone rubber, silicone elastomers, printing inks, cosmetics and unsaturated polyester.

> TERRASIL® PRIMER 6400

Primer for Silicone Rubber

A solution of reactive siloxanes and silanes in an organic solvent. It is used as primer and bonding agent with addition-curing silicone rubbers. It can be applied by various coating techniques like dipping, brushing or spraying.

APPLICATIONS

> Foundry

> Industrial Molding & Die Casting

> Injection Molding

> Liquid Injection Molding (LIM)

> Compression Molding

> Thermal Molding

> Extrusion

> Mold Making

> Silicone Molding

> Prototyp Molding

> Rapid Prototyping

> Die Casting

> Polyurethane Flex Foam Casting

> Polyurethane Elastomer Molding

> Integral Skin Polyurethane Foam Casting

> Polyester Molding

> Aluminum Casting

> Metal Injection Molding

> Shoe Sole Manufacturing

> Automotive Parts Manufacturing

> Door & Window Profile Manufacturing

> Electrical & Electronic Parts Manufacturing

> Wire & Cable

> Cable Accessory Manufacturing

> Insulator Manufacturing

> Surge Arrester Manufacturing

> Silicone Kitchenware Manufacturing

> Silicone Utensil Manufacturing

> Baby Care Materials Manufacturing

> Foot Care Products Manufacturing

> Medical Instruments Manufacturing

> Prosthesis Manufacturing

> Sports Equipments Manufacturing

> Diving Equipments Manufacturing

> Marine Equipments Manufacturing

> Construction Materials Manufacturing

> Building Elements Manufacturing

> Facade Panel Manufacturing

> Home Decoration Articles Manufacturing

> Polyurethane Furniture Parts Manufacturing

> Polyester Furnishing Parts Manufacturing

> Decorative Ornaments Manufacturing