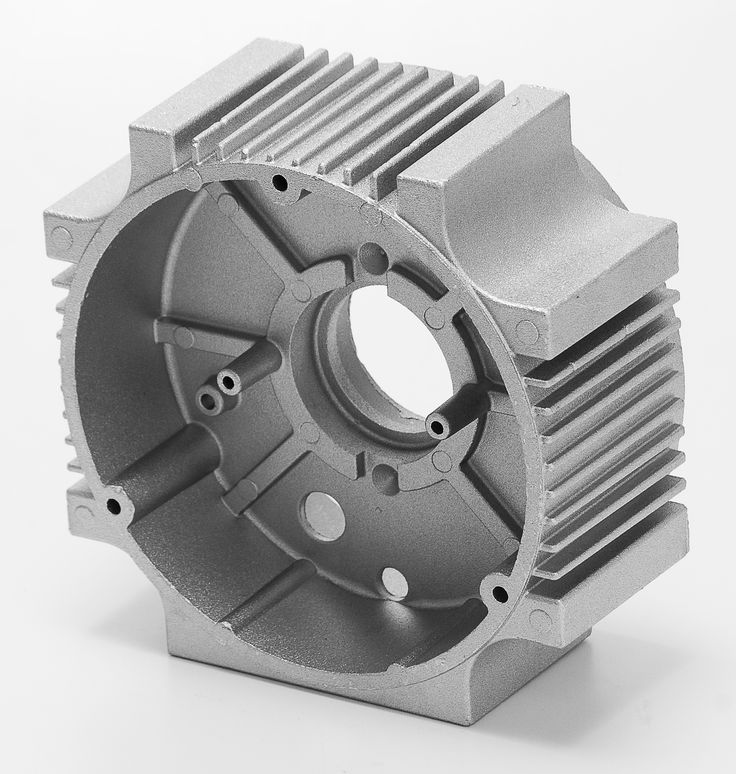

Easy demolding, excellent surface quality

For the industries which manufacture aluminum and light alloy parts under high pressure casting such as automotive parts, engine components, and armatures, TERRA offers a specific range of mold release agents.

Derivated from functional Silicone Fluid and Silicone Resin mixtures, TERRASIL® RA serie silicone emulsions for release have outstanding lubrication and release properties. They are resistant to high temperatures and high temperatures, enable smooth demolding process by providing desired surface quality at the demolded part. In addition, they minimize mold dirtiness, extends mold life, and save in energy, labor and consumption.

Being innovative and sustainable process aids, TERRASIL® RA silicone emulsions used for mold release in aluminum and light alloy compression molding help to increase productivity, enhance final product quality, and contribute to the cost-optimization.

Our tailor-made solutions help you achieve your goals

We are an innovative solution provider for the industries. Offering tailor-made solutions that consider specific processing conditions, we help our clients readily achieve their goals:

> Silicone Emulsion for Release & Lubrication

For further information about our mold release agents used for High Pressure Casting Aluminum & Light Alloy Parts, please contact us. Our experts will assist you in making the right choices to secure the product properties you seek.

PRODUCT RECOMMENDATIONS

> TERRASIL® RA 5050

Silicone Fluid Emulsion

Nonionic oil-in-water emulsion of a polysiloxane containing alkyl and aralkyl organic groups. It is used for the formulation of release agents for the thermal moulding of rubber, plastics, and low-melting non-ferrous metals. It is mainly recommended for release problems where the demoulded parts are subsequently painted, printed, coated or bonded.

> TERRASIL® RA 5055

Silicone Fluid Emulsion

Nonionic oil-in-water emulsion of a polysiloxane containing alkyl and aralkyl organic groups. It is used for the formulation of release agents for the thermal moulding of rubber, plastics, and low-melting non-ferrous metals. It is mainly recommended for release problems where the demoulded parts are subsequently painted, printed, coated or bonded.

> TERRASIL® RSN 1600 MQ

Alkylsilicone Resin (Silicone MQ Resin)

Pure white powder silicone resin. It can be compounded with polydimethylsiloxanes or dissolved in appropriate solvents like aromatic and non-aromatic hydrocarbons or lower alcohols. The solubility is excellent.

> TERRASIL® RSN 3700

Silicone Resin Emulsion

Nonionic/anionic oil-in-water emulsion whose active ingredient combines the benefits of both polydimethylsiloxanes and silicone resins. It can be readily incorporated into cold-stirred formulations.

> WACKER® TN

Functional Silicone Fluid

Modified silicone fluid of medium viscosity whose special chemical structure imbues it with the benefits of silicone fluids and mineral oils. is used for the formulation of release agents for thermal molding of rubber, plastics and low-melting nonferrous metals. It is superior to conventional silicone fluids when the finished parts are subsequently to be painted, printed, coated or bonded.

> WACKER® TNE 50

Silicone Fluid Emulsion

Nonionic oil-in-water emulsion of a polysiloxane containing alkyl and aralkyl organic groups. It is used for the formulation of release agents for the thermal moulding of rubber, plastics, and low-melting non-ferrous metals. It is mainly recommended for release problems where the demoulded parts are subsequently painted, printed, coated or bonded.

APPLICATIONS

> Light Alloy Die-casting

> Aluminum Die-casting

> Magnesium Die-casting

> Titanium Die-casting

> Thermal Molding of Non-ferrous Metals

> Metal Die-casting

> Pressure Part Metal Casting

> High Pressure die Casting (HPDC)

> Pressure Die Casting